FF-FRAME

Climate change, increasing air humidity, and variations in temperature introduce challenges to the exterior envelope of a building and the related building components during construction and operation. The FF-FRAME profiles were designed to withstand moisture and temperature variation. Manufactured using a recycled by-product from the production of PIR insulation, the FF-FRAME profiles are used to frame and insulate window openings on exterior walls for the installation of windows.

During extensive testing, the profile has been found to be highly effective in varying conditions of temperature and humidity and have excellent dimensional stability. Due to the low thermal conductivity of the profile, thermal bridging has a minimal effect on the U value of the wall structure.

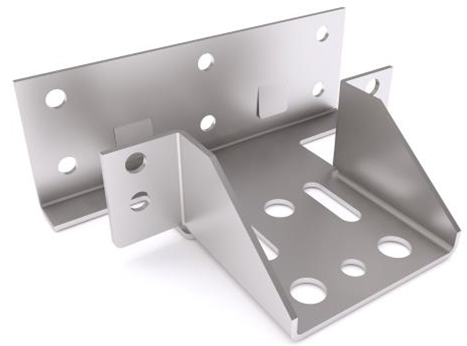

In addition to the auxiliary frame profiles, the FF-FRAME system comprises stainless steel FF-FRAME brackets that are used to install the frames into an existing load-bearing wall. The installation can also be carried out using regular angle iron. When FF-FRAME profiles are fitted at a concrete element plant, they are secured to the element by fitting log bolts or similar hardware onto the edge of the FF-FRAME profile placed against the poured concrete.

FF-FRAME BENEFITS:

- 90% recycled material (crushed PIR insulation).

- High compressive strength.

- Low thermal conductivity 0.089 W/mK, cf. wood 0.14 W/mK.

- Low water absorption (< 5%), cf. wood 60–250%.

- Retains its shape in varying conditions.

- No mold, no rotting.

- Easy to handle and work with.

FF-FRAME:

FF-FRAME 100 | Width, 98 mm | Thickness, 40 mm | Length, 2 750 mm

FF-FRAME 150 | Width, 148 mm | Thickness, 40 mm | Length, 2 750 mm

FF-FRAME BRACKET | Width, 98–148 mm