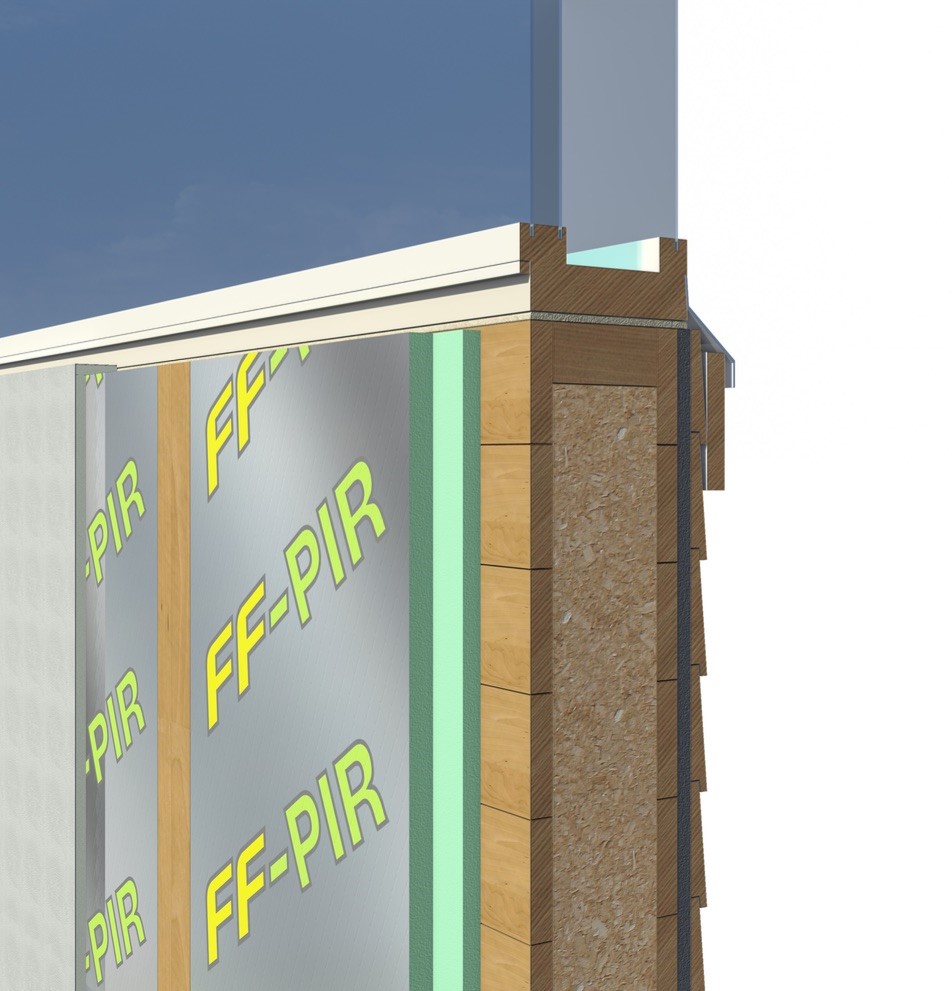

FOR THE REPAIR CONSTRUCTION AND SUPPLEMENTARY THERMAL INSULATION OF ROOFS AND WALLS

FF-PIR insulation products are suitable for insulating walls and roofs in repair construction. When the old porous insulation material is replaced completely with FF-PIR insulation, the energy efficiency of the existing structure can be improved substantially. Another option is to install new insulation panels onto the bottom surface of roof supports or the interior surface of a wall as a continuous layer and seal the seams with an elastic foam sealant and tape. The insulation thickness is determined based on the desired U value or by maximizing the utilization of the space available.

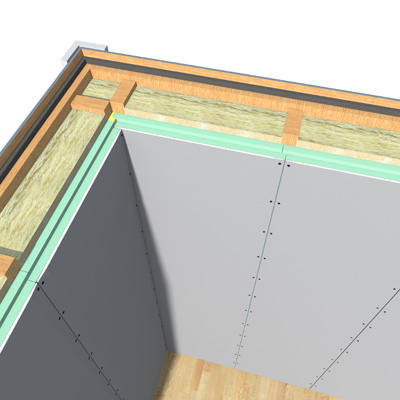

FF-PIR GYL PROVIDES INTERIOR CLADDING AND INSULATION IN ONE PANEL

When a layer of FF-PIR insulation panels is added onto the interior of an existing structure, the insulation panels will function within the structure as both a vapor barrier and supplementary thermal insulation without requiring additional frameworks. The FF-PIR 40/70 GYL products, which consist of a 30 or 60 mm insulation panel to which a 9 mm gypsum board with tapered edges has been glued, can also be used as interior insulation panels for walls. The use of GYL products will significantly speed up the installation process, as a single work element comprises both the thermal insulation and installation of gypsum boards. The mechanical attachment of the panels is carried out according to the instructions provided by gypsum board manufacturers. FF-PIR 40 ALS is another product specifically designed for interior supplementary thermal insulation. The thickness of the panel is 40 mm, and it measures at 600 x 2 600 mm. When joining two panels, a 20 x 100 board can be embedded at the joint. Use an elastic foam sealant and work carefully when constructing supplementary thermal insulation.

Exterior walls

| Framework | Insulation/framework | FF-PIR | U value W/m2K |

| Wood | Sawdust 100 mm | FF-PIR GYL40 | 0,40 |

| Wood | Sawdust 100 mm | FF-PIR GYL 70 | 0,28 |

| Wood | Mineral wool 100 mm | FF-PIR 90 ALK | 0,14 |

| Wood | Mineral wool 100 mm | FF-PIR 30 ALK | 0,23 |

Roofs

| Framework | Insulation/framework | FF-PIR | U value W/m2K |

| Wood | Mineral wool 200 mm | FF-PIR 30 ALK | 0,16 |

| Wood | Mineral wool 300 mm | FF-PIR 90 ALK | 0,09 |

SUPPLEMENTARY THERMAL INSULATION FOR A TIMBER FRAME USING FF-PIR GYL GYPSUM PANELS WITH RABBET EDGES

In a repair construction project, the best result can be achieved by replacing the old insulation material with more effective FF-PIR insulation. You can watch a video below.

SUPPLEMENTARY THERMAL INSULATION FOR WALLS USING FF-PIR RENOVATION PANELS

FF-PIR ALS renovation panels were designed particularly for interior supplementary thermal insulation. Standard rabbet-edged FINNFOAM panels are generally used for supplementary thermal insulation, but if you want to minimize the size of the resulting structure, you can also use FF-PIR ALS renovation panels. The FF-PIR ALS renovation panel consists of polyurethane insulation covered with an aluminum laminate. The thickness of the renovation panel is 40 mm, and it measures 600 x 2 600 mm. The edges of the panel feature 50 mm wide and 20 mm deep rabbets.

The insulation panels are pressed in between the studs of the existing wall and secured in place with batten strips (20 x 100 mm) that fit into the joint between two insulation panels.

The airtightness of the joint can be improved further by applying flexible foam sealant or sealing paste over the seam. This will ensure that the insulation layers is continuous and eliminates thermal bridging. Interior cladding or paneling is attached to the batten strips. As the strips are attached over the seam between the FF-PIR ALS panels, the structure requires very little space and is airtight. It also does not interfere with the behavior of the timber structure and improves the moisture performance of the wall. The top and bottom edges and any pass-through are sealed using elastic foam sealant. This ensures that the new wall is continuous and air-tight, without cold corners or draft.

By renovating an existing wall (U value 0.28) built to the previous standards (in force from 1985 to 2003) with FF-PIR ALS renovation panels, the insulation capacity of the wall can be improved by more than 35%. The newly renovated wall would have an approximate U value of 0.20 W/(m2 K). In reality, the improvement might be even more substantial, as the airtightness of the structure would also be improved. The average leakage rate of a timber-framed house is 4. When airtightness is improved, the energy consumption of the building can be reduced by up to 15% as a result. The airtightness of a structure (leakage rate) is not taken into account in the calculation of U values.

If the renovated wall is even older, the relative improvement in its insulation capacity would be even higher. If an existing wall is insulated with 100–120 mm of porous insulation material, the insulation capacity of the wall could be improved by more than 50 percent with FF PIR ALS renovation panels.

FF-PIR ALS renovation panels offer high thermal insulation capacity and sufficient rigidity. The panels are comfortable to handle and easy to work with. The panels do not crumble or produce dust.

INTERIOR SUPPLEMENTARY THERMAL INSULATION FOR A HEATED BUILDING USING FF-PIR RENOVATION PANELS

FF-PIR ALS renovation panels can be used to create supplementary thermal insulations quickly and cost-effectively. FF-PIR ALS and foam sealant combine to produce a continuous and leak-proof insulation, which also functions as a vapor barrier. If the existing wall includes a plastic vapor barrier, the plastic has to be punctured with approximately 10 holes per square meter. This is done to eliminate areas within the structure that would be placed between two vapor-proof layers.

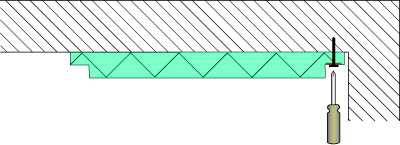

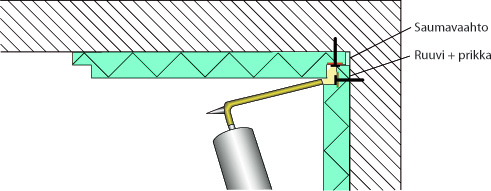

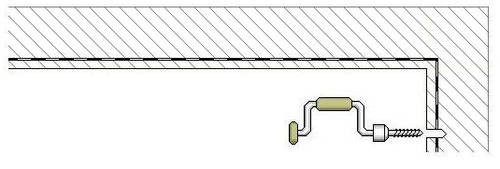

Start insulating from a corner. In the corner, you can use screws and washers to fix the panel in place. Next, seal the end of the panel at the corner using flexible foam sealant. Leave a gap of approximately 10 mm at the top and bottom of the panel to ensure that the foam sealant can be applied easily to the top and bottom seams as well.

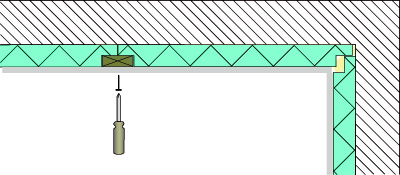

Secure the panels using batten strips (20 x 100 mm). Before you attach the strips, apply some elastic foam sealant into the joint between the panels. The batten strips will push the FF-PIR ALS and the elastic foam sealant against the existing wall, thus ensuring a tight seam.

Interior cladding or paneling can be easily attached to the batten strips. Before you put up the interior cladding, remember to seal the top and bottom edges of the panels and any lead-throughs using elastic PU foam. Sufficient airtightness plays an important part in the energy efficiency of a structure and ensures proper moisture performance! The formula used to calculate the U value of a structure does not consider air-tightness.