SUPPLEMENTARY THERMAL INSULATION USING FINNFOAM INSULATION

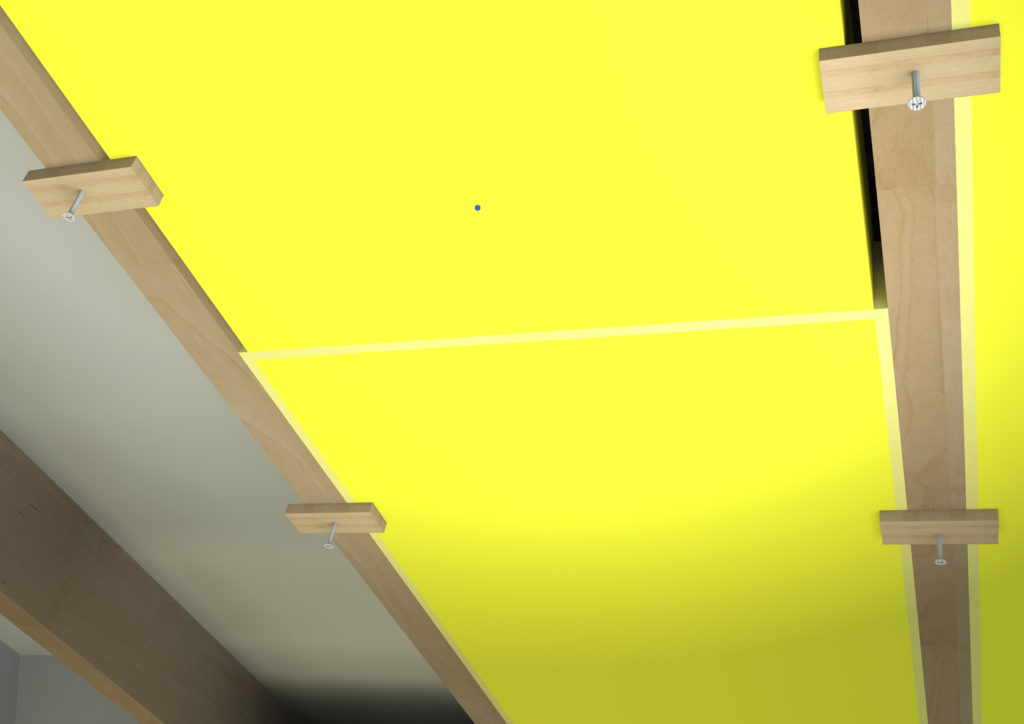

Supplementary thermal insulation can be implemented using standard rabbet edge FINNFOAM insulation panels or FF-PIR polyurethane insulation. If you want to minimize the increase in structural thickness, you can choose the 40 mm thick FF-PIR ALS renovation panels, which feature a 20 x 100 mm groove for batten strips at the edge.

Together with foam sealant and vapor barrier tape, FINNFOAM produces a continuous and leak-proof layer of insulation that also functions as a vapor barrier. FINNFOAM thermal insulation products feature a consistent and fully closed cell structure, which allows them to function as a vapor barrier within structures as well. When using FINNFOAM panels for supplementary thermal insulation, you should always keep in mind that FINNFOAM creates a vapor barrier within the structure, and thus any existing vapor barriers must be punctured (with approx. 10 holes per square meter) or removed. Due to its cell structure, mold cannot grow within FINNFOAM, which has also been verified in mold testing conducted by VTT.

By renovating an existing wall (U value 0.28) built to the previous standards (valid from 1985 to 2003) with 50 mm thick FINNFOAM insulates panels, for example, the insulation capacity of the wall would improve more than 30%. The newly renovated wall would have an approximate U value of 0.20 W/(m2 K). In reality, the improvement might be even more substantial, as the airtightness of the structure would also be improved. On average, the leakage rate of a timber framed house is 4. When airtightness is improved, the energy consumption of the building can be reduced by up to 15% as a result. The airtightness of a structure (leakage rate) is not taken into account in the calculation of U values. Today, you should always maximize the thickness of supplementary insulation – as far as possible in the project – as this will both provide direct savings on the consumption of heating energy and reduce use-phase carbon dioxide emissions.

The improvement of insulation capacity of even older walls would be relatively more significant. If an existing wall has been insulated with 100–120 mm of porous insulation material, the insulation capacity of the wall could be improved by more than 50% with 50 mm of FINNFOAM, for example. The approximate U value of the wall would be 0.25.

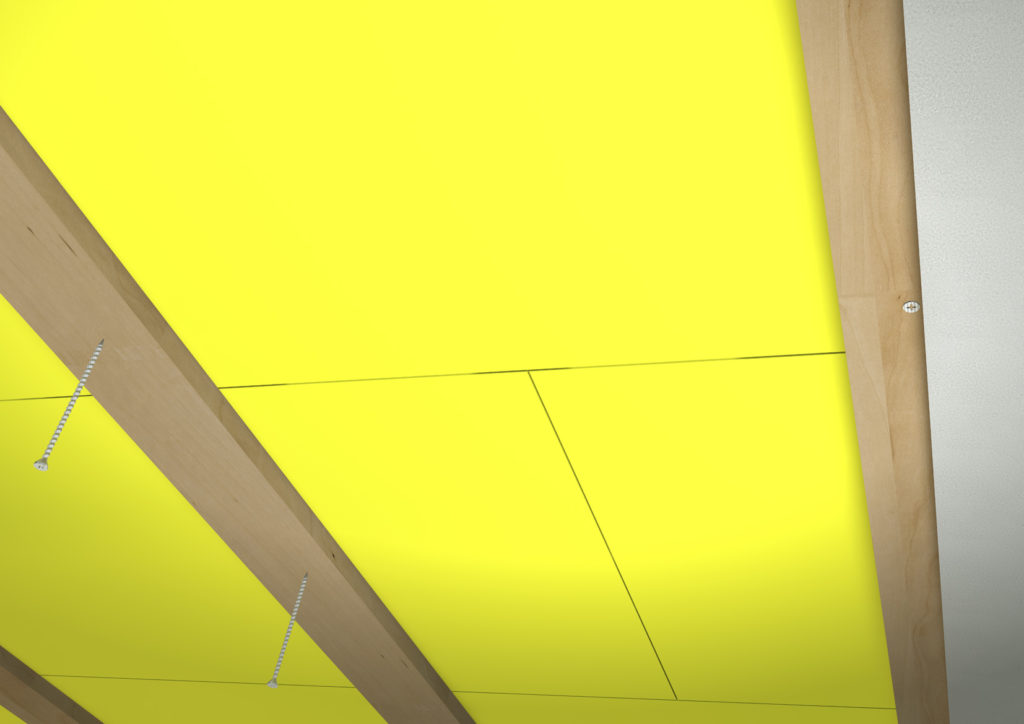

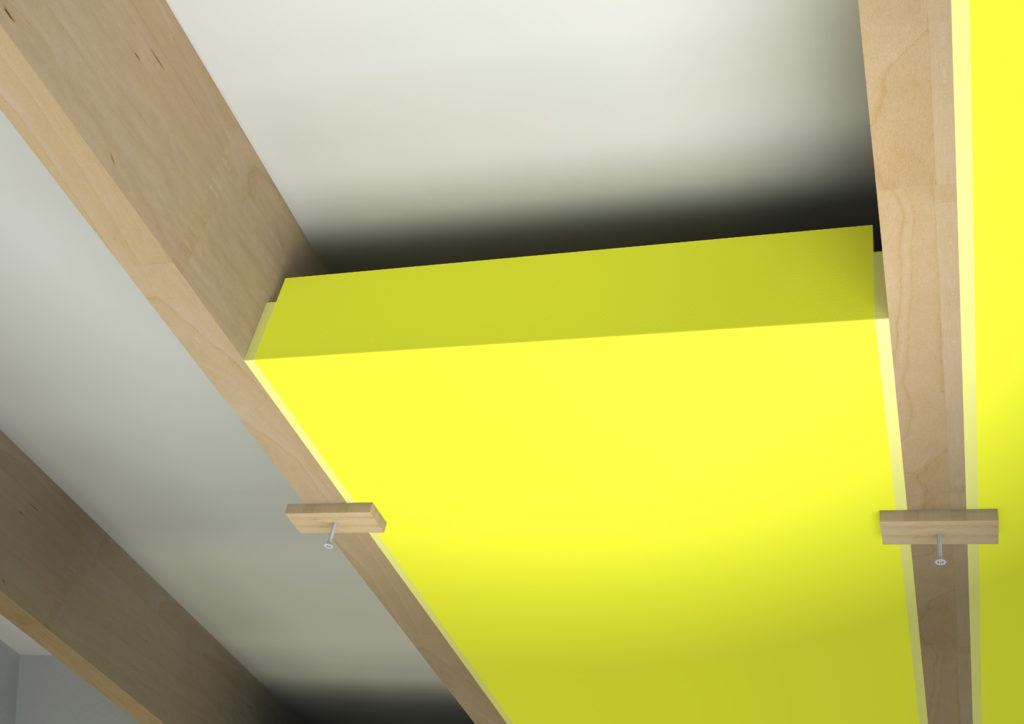

When thermally insulating a wall, always start from the corner and secure the insulation with a studding board on the inside of the FINNFOAM insulation, which is also used to secure the interior cladding. Before you start putting up interior cladding, make sure that the top and bottom edges, joints between panels, and any pass-through are sealed using elastic PU foam and vapor barrier tape. Sufficient airtightness plays an important part in the energy efficiency of a structure and ensures proper moisture performance! The formula used to calculate the U value of a structure does not consider air-tightness.

FINNFOAM panels are comfortable to handle and they can be cut easily with a utility knife or hand saw. The panels do not crumble or produce dust.