Basement Walls

Finnfoam Oy primarily recommends insulating basement walls on the outside either using the standard FINNFOAM insulation panels or CW-300 insulation panels, which are specifically designed for use on basement walls. This recommendation also complies with the National Building Code of Finland. External insulation saves space and allows you to use a solid load-bearing wall to even the temperature of indoor air. By insulating the basement externally with FINNFOAM thermal insulation products, you can also protect the possible waterproofing layer from sharp rocks.

WATCH AN ANIMATION OF INSULATING A BASEMENT WALL!

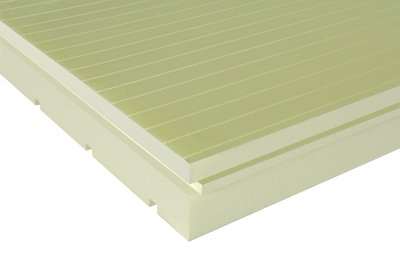

FINNFOAM CW-300/100 MM WAS DESIGNED FOR BASEMENT WALLS AND PROVIDES INSULATION AND A DAMP BARRIER WITH A SINGLE INSTALLATION!

Finnfoam has developed a structural solution for insulating footings and basement walls, which can be used to provide both thermal insulation and tanking for basement walls with a single installation. The structure has been tested by VTT. This structural solution provides significant savings in labor costs and improves the moisture performance of the footing. If the joints between panels are sealed with an elastic adhesive mass or butyl paste (for example: ARDEX CA 20 P, Casco Aquaseal, Sikaflex AT Connection or Sika Lastomer 710 butyl paste), the structure will be completely sealed such that rainwater will gutter down the FINNFOAM material toward the subsurface drains. Moisture from on the inside is able to escape through the grooves (10 x 15 mm) in the FINNFOAM facing the footing. Within the grooves, the partial pressure of water vapor is significantly higher closer to the ground surface than down near the footing due to the temperature differences. Thus, the differences in the partial pressure of the water vapor will force it to travel downward, condensing at the bottom and dribbling down to the subsurface drains.

This structure makes it possible to optimize the moisture performance of the footing based on the laws of physics. Water, or soil carried by water, cannot enter the structure from the outside and thus the performance of the ventilation channels will remain unchanged over decades. The ventilation grooves placed against the foundation within the structure are closed from above, thus preventing moisture from the outside air entering the channels.

This structure makes it possible to optimize the moisture performance of the footing based on the laws of physics. Water, or soil carried by water, cannot enter the structure from the outside and thus the performance of the ventilation channels will remain unchanged over decades. The ventilation grooves placed against the foundation within the structure are closed from above, thus preventing moisture from the outside air entering the channels.

The basement wall insulation (CW-300) also has small fluting (2 x 2 mm) on the exterior surface of the insulation, which allows water to easily pour down into the subsurface drains. The exterior surface of FINNFOAM can be covered with a filter cloth that will protect the flutes and maintain their functionality even under demanding conditions. The subdrainage on the exterior surface of FINNFOAM, which is protected by a filter cloth, also enables external backfilling with foundation soil at renovation sites. This provides cost savings as it reduces the need to transport soil to and from the site. The above-ground section of the FINNFOAM panel is rendered according to the manufacturer’s instructions using an alkali resistant fiberglass mesh. The surface can also be clad using rock boards, in accordance with the manufacturer’s instructions.

The above-ground section of insulation must always be bonded securely to the footing with adhesive mortar (slab or renovation mortar, for example). Mechanical anchors may be used to further secure the above-ground section (Such as Viki brackets from SK or similar products).

FINNFOAM ALSO FUNCTIONS AS A CASTING MOLD FOR BASEMENT WALLS

The sturdy FINNFOAM can also be used as an external casting mold for a basement wall. While water cannot permeate FINNFOAM, it may escape through the joints, which means that it may be necessary to install a damp barrier on the outside.

A ventilation gap is left between the FINNFOAM and the vapor-proof damp barrier (make sure to install the damp barrier facing the right way, i.e., with the studs toward FINNFOAM), which will allow the tiny amount of water vapor coming through the FINNFOAM material to escape. As a small ventilation gap cannot vent large amounts of moisture, the thermal insulation used must be highly vapor-proof like FINNFOAM.

LOW RISK INTERNAL INSULATION – NO GAPS BETWEEN THE WALL AND INSULATION!

Moisture in the ground will attempt to permeate inside through the walls as well, which is why the exterior surfaces of basement walls typically require waterproofing by using bituminous felt, for example. With waterproofing installed on the outside and a separate vapor barrier constructed on the inside, the slowly-drying special structure in between can easily be subject to mold damage if it includes organic or other material susceptible to mold.

Impermeable and mold-proof (tested by VTT) FINNFOAM thermal insulation can be used to provide interior insulation with very low risks, as a separate vapor barrier is not needed on the inside. In this case it is important to bond the FINNFOAM thermal insulation securely to the wall throughout using slab or renovation mortar, for example. Do not leave gaps between the insulation and the wall or use studwork, which could provide suitable conditions for mold colonies. A solid structure consisting of concrete and FINNFOAM withstands moisture and is impermeable. The interior surface of FINNFOAM is warm and the internal cladding will correspond to the relative humidity of indoor air.