MATERIAL-EFFICIENT, STRONGER BASE FLOOR SOLUTION THAT GENUINELY REDUCES THE CARBON FOOTPRINT OF CONSTRUCTION

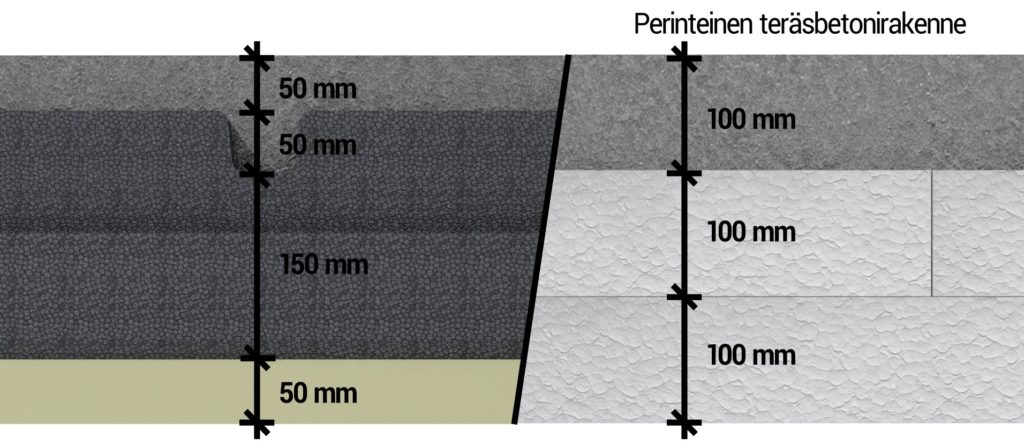

Due to its unique 3D structure, the FF-FLOOR solution for slab-on-ground foundations requires 30 percent less concrete than traditional options, while also increasing the strength of the base floor structure by 20 percent.

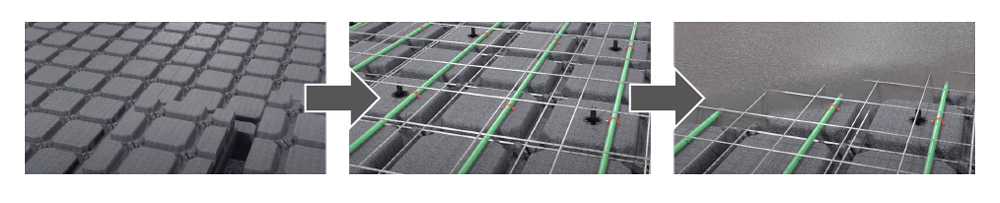

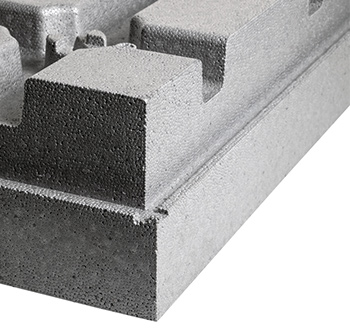

The solution, which utilizes mold technology, consists of insulation panels with lattice-like grooves. The concrete poured on top of the insulation panels with locking tongue and groove joints fills the grooves creating a lattice-like support structure for itself in the base floor. The delivery also includes a custom-made reinforcing mesh designed for the system, which is installed into the grooves in the insulation panels. This eliminates the need to walk on top of the panels at the worksite when using fiber-reinforced concrete, which is also the recommended solution.

FF-FLOOR 100S:

- Panel size 600 x 1 200 mm

- Functions as both thermal insulation and casting mold for slab-on-ground foundations

- Two-way fluting 50/60 x 50 mm k/k300 mm

- Steel brackets for mesh #300 at the grooving intersections (separate plastic reinforcing bar spacers are not required).

BENEFITS:

FF-FLOOR 100-mm concrete slab vs. traditional 100-mm concrete slab:

- Amount of concrete reduced by 30% = smaller carbon footprint

- Strength of the concrete slab increased by 20%

- Faster installation: one solid layer of insulation material + steel mesh #300

- Consumption of steel is reduced

- The concrete slab dries more quickly

- The concrete and the insulation material adhere better to each other

PRODUCT VIDEO:

BASIS FOR STRUCTURAL DESIGN:

Tensile reinforcement of the concrete slab (using the grooves in FF-FLOOR) and the total thickness of the slab based on structural design (recommended minimum thickness of the slab is 100 mm from the base of the groove).

OPERATION:

- FF-FLOOR 100S/200 mm meets the U-value requirements specified for conventional base floors.

- Alternatively, you can also use two layers of insulation with FINNFOAM 100 mm on the bottom and FF-FLOOR 100S/100 mm on top.

- The high water vapor resistance of FINNFOAM insulation products significantly improves the moisture performance of the base floor and facilitates the installation of insulation on top of crushed stone.

- The 6-mm steel reinforcements placed into the grooves bear the load of the slab.

- The section of FF-EPS in between the two-way fluting functions as lightening for the slab.

- Any drying shrinkage in the slab is countered using 4-mm steel mesh on top or fiber-reinforced concrete, which is the recommended option.

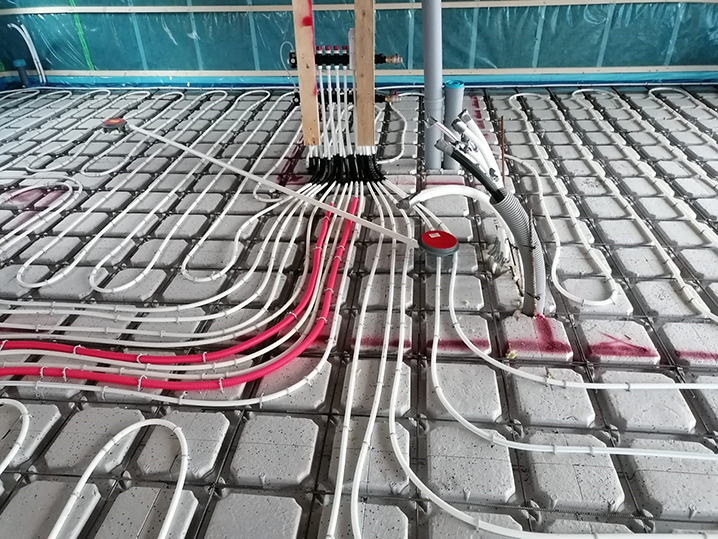

SECURING THE UNDERFLOOR HEATING PIPES:

- To the steel reinforcement on the upper surface

- When using fiber-reinforced concrete, secure pipes to the surface of the FF-EPS with plastic U-shaped brackets and tensile reinforcement where necessary.

INSTALLATION PHOTOGRAPHS:

PASSIVE GROUND HEAT PROVIDES A BOOST

Passive ground heat improves the moisture performance of a floor when the soil beneath the insulation remains sufficiently cool. Particularly in the winter, overheated soil (approximately 17–20 °C) can generate significant amount of water vapor rising from the ground (into dry indoor air). A passive ground heat pipeline will cool down the soil, while simultaneously preheating the fresh replacement air. FINNFOAM and FF-XPS 200 LATTIA can slow down the flow of water vapor from the ground toward the building effectively, thus allowing for the concrete to be coated with an impermeable material, which is always necessary in wet rooms.

The liquid circulating inside the passive ground heat pipeline will only require a circulation pump rated for 15 W to increase the temperature of fresh outside from -15 to +5 degrees in the winter. Correspondingly, the system can cool down outdoor air from +30 to +22 degrees in the summer.

Although the entire structure is gray in color, it has a green heart. FF-XPS 200 LATTIA is partially manufactured from recycled plastic, which is recovered from construction sites using FF-Kierrätyssäkki bags. FF-XPS 200 LATTIA uses recycled carbon dioxide as a propellant. The insulation products are manufactured using green electricity, some of which is generated with our own solar panels.