Ventilated Base Floors

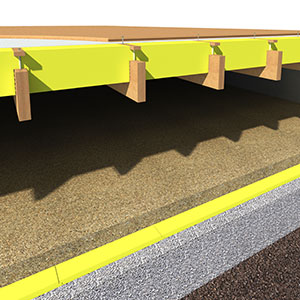

A ventilated base floor is the safest foundation method in terms of moisture performance and radon. The FINNFOAM product range includes solutions to all types of structural solutions for ventilated base floors.

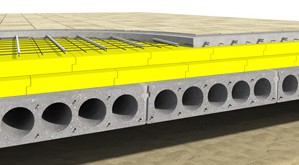

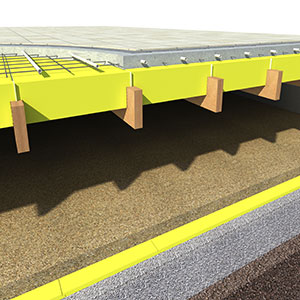

In a ventilated base floor structure that uses a hollow-core concrete slab, FINNFOAM insulation should be placed on top of the slab. This type of structure will minimize thermal bridging and ensure fire safety. It will also ensure the energy efficiency of any underfloor heating systems that may be installed, as the structure will allow underfloor heating to react quickly to changes in outdoor temperature without wasting energy on heating the hollow-core slab.

FINNFOAM VENTILATED BASE FLOOR INSULATION:

When constructing a ventilated base floor structure with a hollow-core concrete slab or timber joists, it is extremely important to cover the foundation soil at the bottom of the crawl space with thermal insulation material that offers high water vapor resistance. A 10–20 cm layer of sand is placed on top of FINNFOAM to keep the insulation in place and to facilitate movement within the crawl space. This will significantly improve the moisture performance of a ventilated base floor, as the length of the condensation period in the spring is reduced due to the quickly heating crawl space. In addition, FINNFOAM will prevent moisture released from the ground from reaching the base floor structures.

PRODUCT VIDEO:

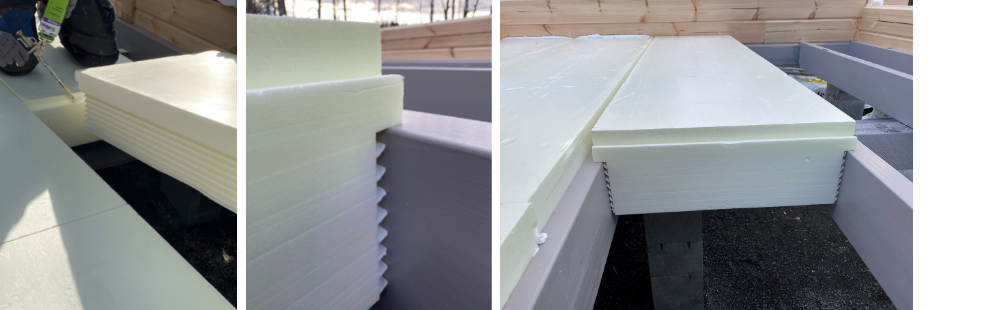

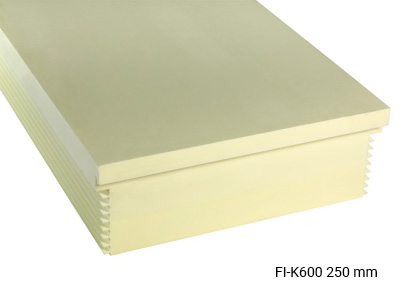

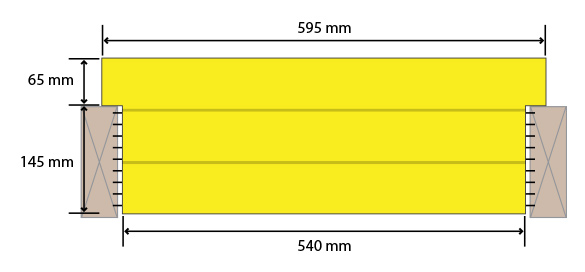

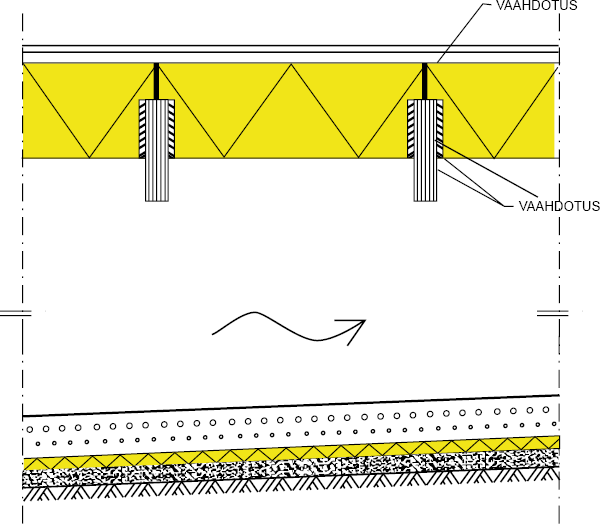

The ventilated base floor insulation products FI or FL-K600 developed by Finnfoam are available in thicknesses of 210, 250, and 370 mm, depending on the project’s U value requirement. Each panel type offers the same thickness of insulation on top of floor joists, which is 65 mm. The high compressive strength (200–700 kPa, or 20–70t/m2) and rigidity of FINNFOAM allow for simplified ventilated base floor structures. The ventilated base floor can be completed quickly and it can be walked on immediately after installation, thus reducing the need to walk on top of the supporting rails, which can be hazardous. Due to the strength and waterproofing of FINNFOAM thermal insulation, the ventilated base floor can be insulated first, thus providing a solid foundation to start building the walls and roof. The joints are sealed with an elastic/flexible PU joint foam before casting or once the roof-covering sheeting has been installed.

The entire thermal insulation, wind-proofing, vapor barrier, and casting mold required for a ventilated base floor can be completed within a single stage in just few minutes. The low number of stages makes installation highly cost-effective.

A concrete floor can be constructed directly on top of the FINNFOAM ventilated base floor insulation with hydronic underfloor heating and any other technical solutions required. Another option is to lay plank flooring on top of the ventilated base floor insulation, or use flooring panels as a distributive layer, on top of which you can lay laminate or parquet flooring.

The short-term bearing capacity of a FINNFOAM ventilated base floor is little over 1 700 kg/m2, and the long-term capacity little over 800 kg/m2. The bearing capacity of the material is similar to a ventilated base floor with crosswise supporting rails. The insulation is designed for 50 mm floor joists with an on-center spacing of 600 mm (K600) and has a tolerance of ±10 mm. If the floor joists are thicker than 50 mm, the space in between the joists must, however, always be 550 mm.

The FINNFOAM ventilated base floor insulation is installed on the inside between the supporting rails. The insulation is designed for floor joists measuring 48 mm or wider and has a tolerance -10… +10 mm for the support spacing. If the floor joists are thicker than 50 mm, the space in between the joists must always be 550 mm regardless. The impermeable FINNFOAM insulation does not require separate wind-proofing or vapor barriers. FINNFOAM panels are sturdy enough to walk on immediately after installation. This eliminates unsafe moving over the supporting rails. As FINNFOAM thermal insulation products are waterproof, they can be installed even where roof covering does not yet exist.

In case of water damage, FINNFOAM will not get waterlogged and instead dries quickly, as the closed cell structure does not allow moisture to permeate the insulation. The mold risk is also minimized when all surfaces dry quickly. The interior seams of the panels are sealed with a flexible polyurethane foam. Foam can also be applied to the exterior seams, but this is usually unnecessary.

THEORY OF THE MOISTURE PERFORMANCE OF A VENTILATED BASE FLOOR

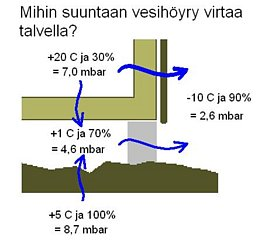

A fully ventilated base floor that is not surrounded by footings is the safest possible solution with regard to radon. This type of structure is also very effective in terms of moisture performance. The temperature and moisture content of the crawl space correspond fully to the outside air conditions. If the crawl space is surrounded by footing, the situation changes significantly. The U value requirement for a pillar-based ventilated base floor (0.09) is nevertheless significantly higher than that of closed footing structures (0.17). Thus, ventilated base floor foundations are usually built with closed footings.

The average ground temperature is very close to the yearly average temperature. This can be easily observed in a root cellar, where the temperature remains quite stable throughout the year. The relative humidity of the ground is always 100%. These two factors result in a moisture risk, which is at its highest in the spring when the crawl space is significantly colder than outside air. The warm air coming from the outside increases the humidity, which condensates on all surfaces due to the lower temperature in the crawl space where the ground remains cooler for a long time. This can be prevented, or at least reduced significantly, by insulating the subgrade surface (we recommend installing 30 or 50 mm of FINNFOAM throughout). This will allow the temperature of the crawl space to closer follow the temperature of the outside air, and thus eliminate condensation. FINNFOAM is also highly effective in preventing moisture from rising up from the ground (water vapor), which occurs when the ground temperature is higher than the temperature of the crawl space or the relative humidity in the crawl space is low. The goal here is to maintain the lowest possible humidity in the crawl space.

EXAMPLE A – VENTILATED BASE FLOOR IN THE SPRING AND SUMMER:

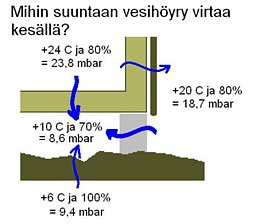

When the ground temperature is +5° C, the partial pressure of water vapor in the pore space of soil is approximately 8.7 mbar (100%). If we want the relative humidity of the crawl space to reach a maximum of 70%, the temperature of the crawl space should be +10° C or higher (partial pressure of water vapor 8.7 mbar) to ensure that water vapor does not rise from the ground into the crawl space. Water vapor will always flow from higher pressure toward lower pressure! FINNFOAM thermal insulation placed on the ground surface will prevent water vapor from rising up from the ground and heat in the crawl space from transferring to the ground.

In order to ensure that the air flowing in from the outside reduces humidity inside the crawl space instead of the opposite, the outside air must be drier than the air inside the crawl space. Therefore, if the temperature of the crawl space is +10° C and relative humidity is 70% (partial pressure of water vapor 8.7 mbar), the RH of the outside air should at most be 80% and the temperature +8° C. In the spring and summer, ventilation air can thus easily introduce more humidity into the crawl space, as the outside air is warmer than the crawl space. FINNFOAM thermal insulation will prevent heat from transferring to the ground, which allows the temperature in the crawl space to rise quickly with the temperature of the outside air, thus reducing relative humidity in the crawl space.

EXAMPLE B – VENTILATED BASE FLOOR IN THE FALL AND WINTER:

Cold air reduces moisture within structures effectively. The partial pressure of water vapor in outside air with a relative humidity of 90% and temperature of -10° C is only approximately 2.6 mbar, and the moisture content is 1.8 g/m3. When air inside the crawl space reaches +1° C, its moisture content is already 3.5 g/m3, and the partial pressure is 4.6 mbar when relative humidity is 70%. If the ground temperature is +5° C, the partial pressure of water vapor in the soil is 8.7 mbar. In this case, water vapor will be released from the ground at 4.1 mbar (8.7–4.6). Impermeable FINNFOAM thermal insulation will prevent water vapor from rising from the ground to the crawl space!