USING FF-EPS INSULATION AS THERMAL INSULATION FOR EXTERIOR WALLS

FF-EPS 60 S is a cost-effective thermal insulation product for walls that offers safe moisture performance and has a declared thermal conductivity (λD) of 0.031 W/mK. FF-EPS insulation products are suitable for new construction, low-energy, passive, and zero-energy construction, as well as for supplementary thermal insulation of older buildings.

FF-EPS 60 S insulation products can be used with various framework materials. Frames can consist of wood, steel, concrete, precast concrete, brick, lightweight concrete (Siporex), or breeze blocks. Structures that are thermally insulated with FF-EPS usually require a separate air or vapor barrier layer as the product does not have a high enough water vapor resistance to function as vapor barrier on its own. We recommend using elastic PU foam sealant for the seams and joints between panels.

FF-EPS INSULATION PRODUCTS ARE SUITABLE FOR ALL WALL STRUCTURES

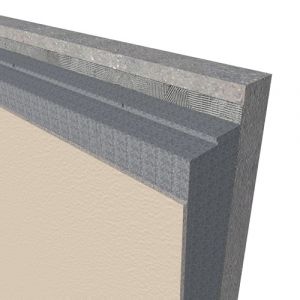

As a framework material for an exterior wall, rock (concrete, brick, breeze block) provides an excellent base for FF-EPS. The exterior surface of FF-EPS 60 S panels can be clad with wood facing, or thin-coat render may be applied directly onto the surface of an aged FF-EPS ETICS panel. FF-EPS insulation panels with locking tongue and groove are installed on the outside of the framework as a continuous layer of insulation by, for example, bonding the panels with mortar or attaching them with a PU foam adhesive to a supporting wall and securing the attachment with a few mechanical anchors. A concrete wall that is thermally insulated with FF-EPS insulation does not require an additional vapor barrier. The thickness of insulation is determined according to the desired U value. For example, a U value of 0.17 can be achieved with a 180 mm of FF-EPS insulation. To approach true zero-energy levels, walls should have a U value of at least 0.12, in which case the required insulation thickness is 250 mm.

The framework of the exterior wall may also consist of wood, in which case the structure can be constructed as follows: FINNFOAM or FF-PIR thermal insulation panels are installed onto the interior surface of studs or between them, which also function as vapor barrier within the structure. A continuous layer of FF-EPS panels is installed on the exterior of the framework. The thermal conductivity of the layer of FF-EPS panels on the outside of a load-bearing framework must be as high or higher as that of the FINNFOAM or FF-PIR insulation in between the framework elements to insure correct moisture performance. The thickness of insulation is determined according to the desired U value. With a timber frame, the exterior face is constructed as a ventilated structure.

You can find more information on the properties of FF-EPS panels as well as the panel types and dimensions here.