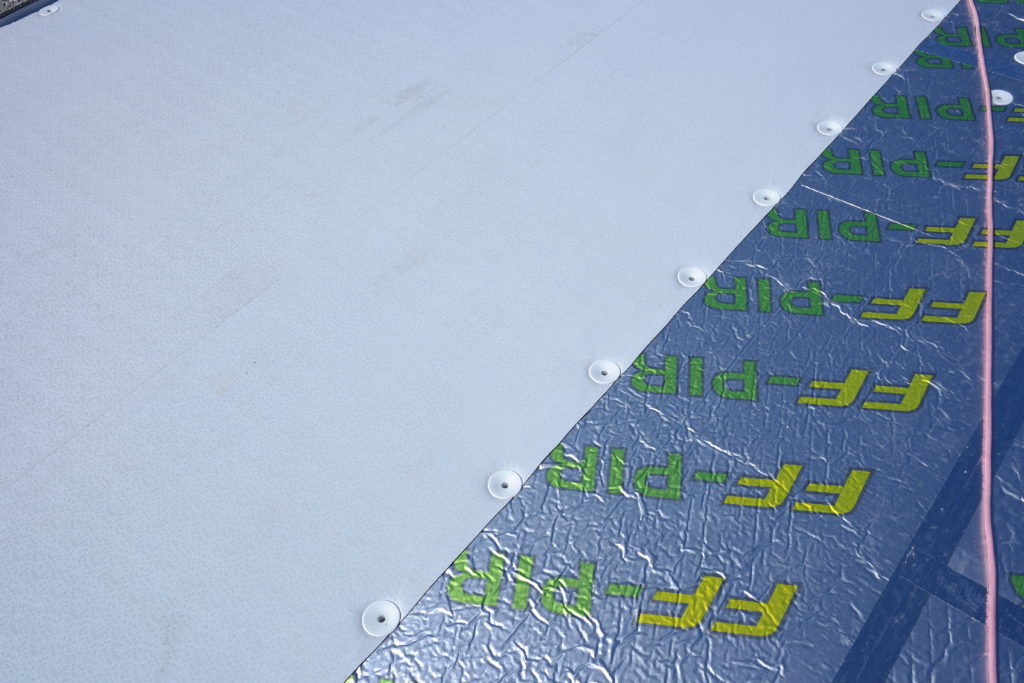

Low Pitch Roofs (FF-PIR)

When used on large low pitch roofs, FF-PIR insulation products boost the efficiency of construction, as the installed insulation is among the thinnest options available on the market. FF-PIR insulation ensures quick installation, requires less lifting of materials onto the roof, and is compatible with almost all roofing solutions on the market. FF-PIR AL or FF-PIR BI insulation products, which includes a bitumen laminate that can be used to install bitumen sheeting directly over the insulation panels, are most commonly used for low pitch roofs.

The FF-PIR BIL panels with a bitumen laminate surface and FF-PIR ALK panels with an aluminum surface offer a quick and cost-effective solution for low pitch roofs. FF-PIR BIL and FF-PIR ALK panels can be used directly as a sturdy base for roofing as well as solar panels and various technical equipment installed on modern roofs.

FF-PIR ALK is secured mechanically to the backing in accordance with the designer’s instructions, and BROOF (T2) tested PVC or bitumen sheeting is bonded to the FF-PIR ALK panels.

FF-PIR BIL is secured to the backing with an adhesive, by welding, and/or mechanically in accordance with the designer’s instructions. When the structure comprises more than one layer of insulation, the FF-PIR BIL panels are secured to the base with an adhesive and to the roofing with mechanical fittings. BROOF (T2) tested bitumen roofing sheets are welded, glued, and/or mechanically attached to the FF-PIR BIL panels.

Certain U values can be achieved for low pitch roofs using the following insulation thicknesses:

U value 0.09 W/m2K (advisory)

Backing – FF-PIR ALK 150 mm + FF-PIR BIL 100 mm

U-value max 0.14 W/m2K.

Backing – FF-PIR BIL 100 mm + 80 mm

Backing – FF-PIR ALK 120 mm + FF-PIR BIL 50 mm

SOME EXAMPLE STRUCTURES ARE PRESENTED IN THE BELOW CHART

Comparison of insulation thickness

Framework | Insulation/framework | FF-PIR | U value W/m2K |

| Hollow-core slab | Insulation on top of hollow-core slab | FF-PIR 120 + 120 mm | 0,09 |

| Double T-slab | Insulation on top of slab | FF-PIR 120 + 120 mm or alternatively FF-PIR 240 mm + a 20-mm bearing layer of wool | 0,09 |

| Corrugated sheet steel | 40 mm stone wool below | FF-PIR 100 + 100 mm or alternatively FF-PIR 200 mm + a 20-mm bearing layer of wool | 0,09 |