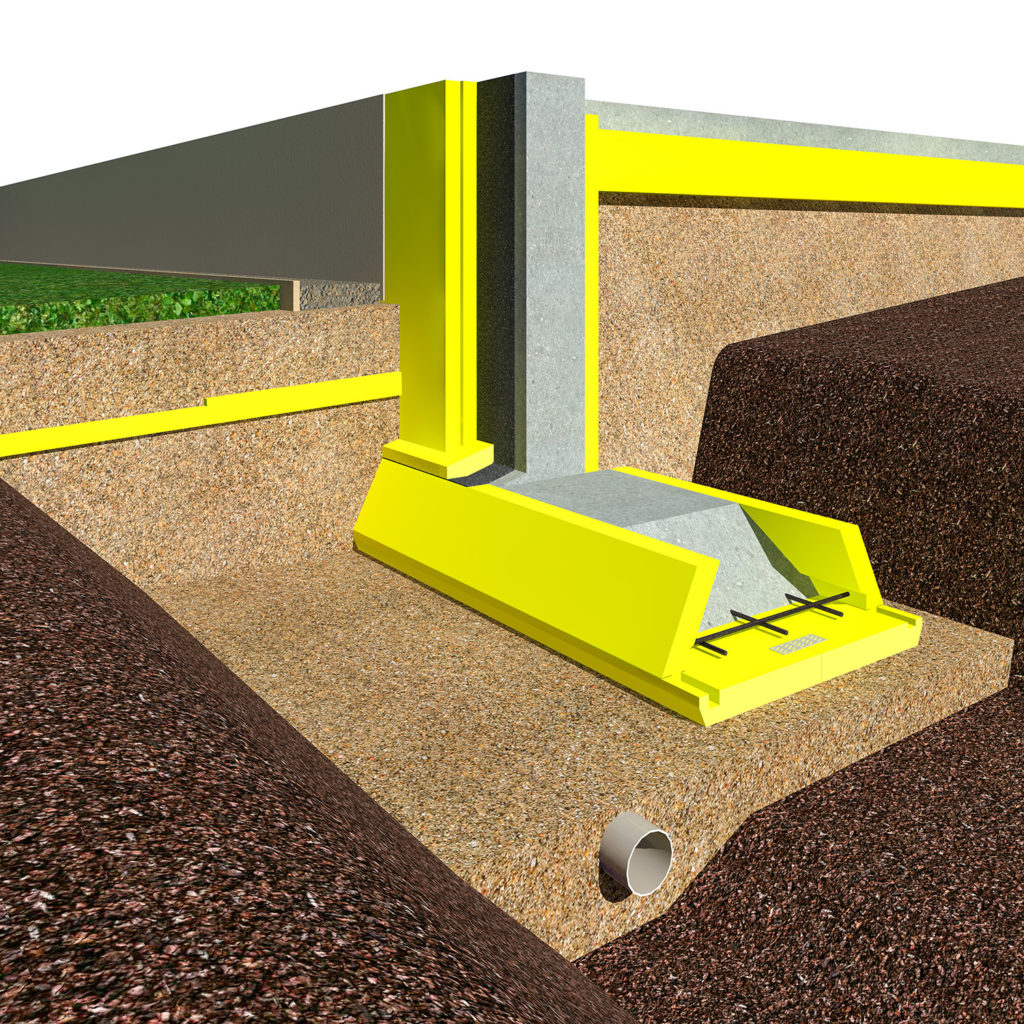

Slab Foundation and Pillar Molds

FINNFOAM SLAB FOUNDATION MOLDS ALLOW YOU TO PRODUCE FOUNDATIONS QUICKLY AND EASILY.

In accordance with the SKOL / hEN Helpdesk product specification instructions: The insulation placed under a slab foundation must have been subjected to a test for compressive creep over 50 years. FINNFOAM has been tested in this manner, and it is highly resistant to sustained long-term loading. When following good modern construction practices, insulation that prevents thermal bridging should always be installed underneath a slab foundation.

INSTALLATION INSTRUCTIONS

EKO SLAB FOUNDATION MOLD 200 × 600/400 MM

- Bend the panel at the crease to separate the bottom and wall sections.

- Place two bottom pieces next to each other such that the rabbet edges are at the sides for attaching the walls. Secure the bottom pieces to each other using insulation brackets.

- Place the wall pieces to the rabbet grooves of the bottom pieces. Overlap the joints such that lateral seams on the bottom and wall pieces do not run across each other.

- Installing the corners: Cut all the bottom pieces used for the corner to the required angle and secure them to each other using insulation brackets.

- Mark the angles of the wall panels on the butt joint by using the relevant panel as a template. Cut and install the wall panels onto the rabbet grooves on the bottom pieces. The same principle applies to corners on both exterior and interior walls.

- Reinforcement and pouring: Reinforcement for the EKO slab foundation mold is constructed according to the structural designer’s plans. Place sufficient number of reinforcement risers underneath the length-wise main reinforcing bars. Secure the length-wise reinforcing bars to each other using lateral bars.

- When pouring the EKO slab foundation mold, you should aim to minimize the pour pressure. The walls of the mold can withstand regular pour pressures without separate supports. It is still advisable to use backfill, for example, to support the walls. When compacting fresh concrete with a concrete vibration, sufficient caution should be observed.

- The concrete surface is honed, reinforcing rods installed, and maintenance of the concrete are carried out in accordance with the plans of the principal and structural designer.

SLAB FOUNDATION MOLD 460 × 580 MM

- Place down the foundation mold such that each upright wall secures two bottom panels together.

- The slab foundation mold is reinforced according to the structural plans of the site.

- Create the external supports for the slab foundation mold using 50 × 100 lumber. If the casting height is 400 mm or less, the walls can be supported with a single horizontal support made from 50 x 100 mm lumber, which is installed at an approximate height of 200 mm. Correspondingly, casting heights of 400–600 mm will require 2 horizontal 50 × 100 mm supports. The horizontal supports are placed evenly at the midpoint and the top edge of the mold. Place two vertical 50 × 100 mm studs a little over one meter apart from each other.

- In between the two upright studs, push a reinforcement bar through the insulation at the vertical midpoint such that it goes through the vertical insulation on the opposite side and the two opposing 50 x 100 lumbers. Finally, use mold clamps to lock the ends of the reinforcement bar in place. This will ensure that the tall FINNFOAM foundation mold is supported securely.

- The concrete is poured in the regular manner.

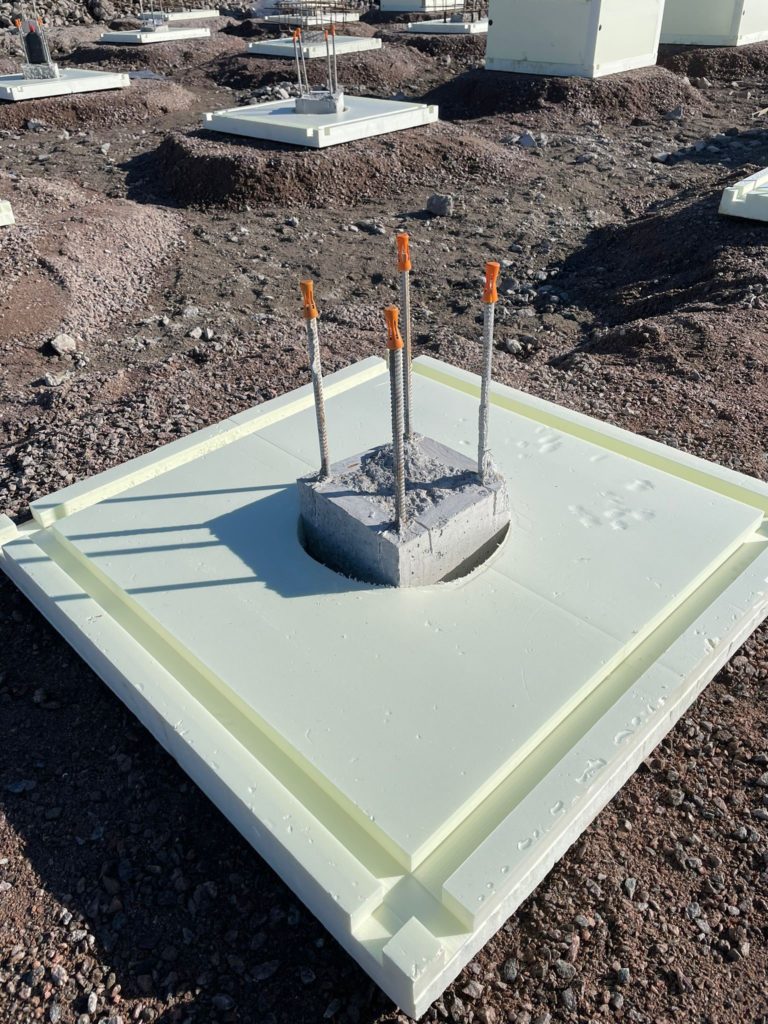

PILLAR MOLD

PILLAR MOLD 500 X 500 X 285 MM

The FINNFOAM pillar mold was designed specifically for insulating pillar foundations. Cold structures, such as decks and buildings with pillar foundations, should always be insulated throughout against frost. The frost insulation should extend far enough beyond the edges of the structure to ensure that frost cannot breach the insulated area at the edges to impact the structure. The FINNFOAM pillar mold was designed specifically for this purpose, and they make the construction of foundations easier, as there is nothing to dismantle after the pour. The pillar mold consists of specially designed 50 mm thick F-300 strength class FINNFOAM (XPS) insulation panels. The upright walls of the mold are slotted into the grooves on the bottom panel to create a sturdy pillar mold. The internal dimensions of the mold are 500 x 500 x 285 mm. The pillar molds are reinforced using FINNFOAM binding tape during installation if the thickness of the concrete pour is 200 mm or lower. If the pour exceeds 200 mm, molds are supported from the outside.

PILLAR MOLD 1 000 X 1 000 X 500 MM

Our product range has been expanded to include a pillar mold that was designed for large-scale construction projects. The internal dimensions of the mold are 1 000 x 1 000 x 500 mm. The construction of large pillar molds has never been easier or faster. No dismantling is required after the concrete has been poured, and the mold is also unbeatable for wintertime construction as it is made from FINNFOAM F-400. As the insulation thickness of the mold is 100 mm, it only has to be supported at the top end to withstand pour pressure.