Pipe Trenches

Pipe trenches and sewer pipelines are traditionally laid down at a frost-free depth to avoid freezing and frost damage. Deep pipeline trenches reaching below the groundwater surface may lead to the lowering of the groundwater surface, subsidence of streets, pipelines, and buildings in areas with softer soil, changes in vegetation in the area, and possibly other environmental nuisances as well.

Where possible in terms of the lowest floor levels of the buildings for which sewer pipelines are being laid and the pitch and relief of yard areas, you can use thermal insulation material to protect the water and sewer pipelines laid in the ground above the frost limit and thus prevent freezing and frost damage.

DOWNLOAD INSTALLATION INSTRUCTIONS HERE:

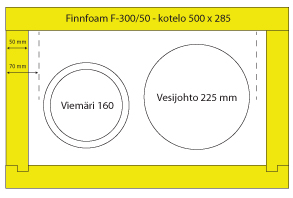

Installing both the incoming water and outgoing sewer pipelines side by side within a sand-filled pipe enclosure made from FINNFOAM provides an affordable method for creating a heat exchange, where heat from waste water is harnessed to prevent the water pipeline from freezing, thus making it possible to reduce the sinking depth.

PRODUCT VIDEO:

PROPER INSULATION PREVENTS FROST DAMAGE

The thermal insulation and frost protection of water and sewer pipelines is based on the utilization of ground heat and the heat released by the pipelines. The insulation slows down the escape rate of heat in the wintertime and prevents the pipeline from freezing by maintaining the freezing zone at the location of the pipe above the crown of the pipe. This also prevents the ground from freezing and pipeline damage resulting from frost heave.

DESIGN CONSIDERATIONS

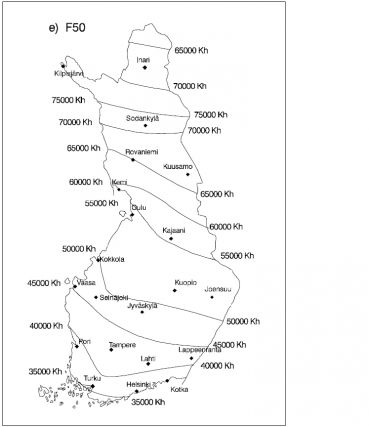

Things to consider while designing frost protection include the climate conditions, soil conditions, and heat released from the pipeline. The insulation of pipelines is designed on the basis of the harshest winter experienced in the area, i.e., the maximum freezing index F50 occurring at least once every 50 years.

SOIL IMPACT

In addition to the climate conditions, the frost-free founding depth of a pipeline depends significantly on the quality of the soil. In sandy and gravel soil, as well as in coarse till-derived soil, the freezing zone is larger compared to clay or silt soil, due to the higher thermal conductivity of coarse soil types and the lower accumulating capacity. Correspondingly, the insulation requirements for pipelines laid into shallower trenches are higher in coarse non-cohesive soil than in cohesion soil with a high water content. The potential to utilize ground heat in the insulation pipelines laid down to shallow rock trenches is also limited, due to the high thermal conductivity of rock and the minimal amount of heat stored by the rock.

In frost-susceptible clay and silt soil, as well as in finer till-derived soil, pipelines are insulated using horizontally placed insulation panels (see the enclosed figure). In areas that are significantly susceptible to frost, a transitional structure is used to even out sharp differences in frost heave.

The most appropriate option for frost-resistant sand and gravel soil, as well as coarse till-derived soil, is to use a rounded U-shaped insulation structure that reaches around the sides of the pipeline, which will maximize the utilization of the heat released from the pipeline (see the enclosed figure).

Pipelines laid down into shallow rock trenches are protected efficiently with an insulation structure that encloses the pipeline (see the enclosed figure). The flow rate in the pipeline and the water temperature must be sufficiently high to prevent the pipeline from freezing. Where necessary, electric heating cables are used as an additional source of heat to ensure that the pipelines remain functional.

RECOVERY OF HEAT FROM WASTEWATER

Based on the type of pipeline, the release of heat can be utilized in the design of the insulation. A rainwater drain may have a cooling effect on the pipes laid beside it due to the flow of cold surface water and ventilation. Conversely, the heat released by sewer and water pipelines laid down into the same trench can usually be taken into account in the design of the insulation. If a specific decrease in temperature is allowed over the insulated section for the fluid flowing through the pipeline, and if this additional heat is continuous during the frost period, it can be included in the calculations as a reducing factor.

INSTALLATION DEPTH AFFECTS COSTS

The installation depth of pipes has a significant effect on the construction cost of the pipeline, more than half of which usually consists of the costs of digging, excavation, installation, and backfilling. Shallow installation in soft soil areas can also be used to reduce the need for foundation reinforcement, as the load resulting from backfilling is decreased, to shorten the construction time, and possibly to avoid supporting the trench during construction. In this type of a situation, the cost savings achieved may be quite significant.

The frost protection for pipes may case-specifically be designed using the design charts included in the below diagrams.

Horizontal insulation thickness in mm (FI-300) and width as a function of additional heat in various ground conditions.

Enclosure-type insulation heat resistance and with as a function of additional heat in rock trenches.

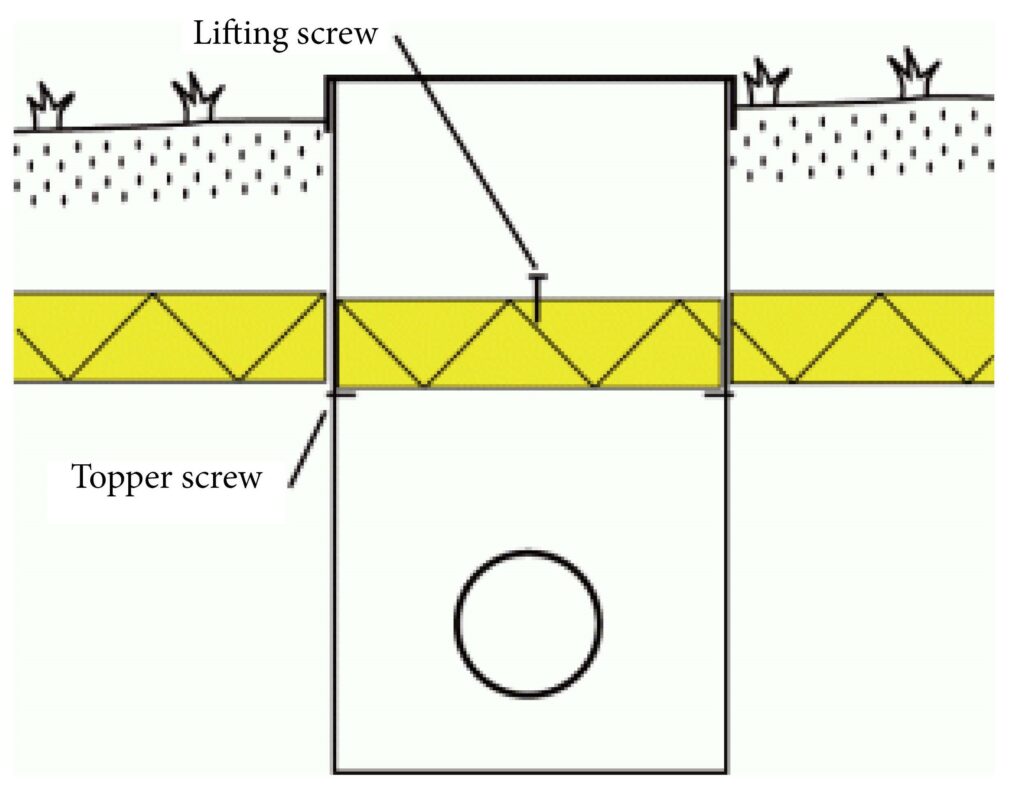

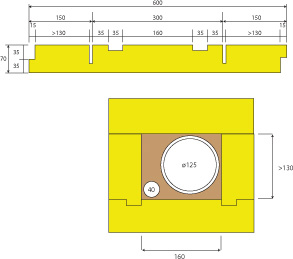

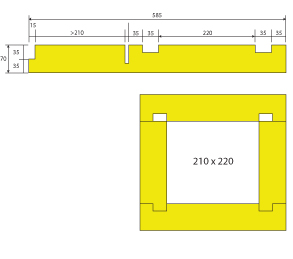

FROST PROTECTION FOR WELLS

Drainage wells are susceptible to thermal bridging. FINNFOAM can be easily cut to fit the shape of a drainage well. The cut piece provides a convenient cover inside the drainage well, which should be as tight-fitting as possible. The sturdy, rigid, and waterproof FINNFOAM insulation forms a durable cover. Screws are placed to the side of the well at the same height as the surrounding frost insulation. It is also advisable to insert a screw into the cover to allow you to lift it up easily.

The same principle can be applied to protect other wells from freezing as well. FINNFOAM insulation is rigid enough to ensure that it will not sag even where the span length is wider.