MOISTURE PROPERTIES

| Moisture properties | CE marking in accordance with EN13164 | F-200 | F-300 | F-400 | F-500 | F-700 |

| Absorption of water when immersed 28 days (t%) | WL(T)0,7 | <0,7 | <0,7 | <0,7 | <0,7 | <0,7 |

| Freeze-thaw resistance (300 cycles) (t%) | FTCD2 or FTCD1 | ≤ 2 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 |

| Absorption of water with diffusion | WD(V)1 or WD(V2) | ≤ 1 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 1 |

| Water vapor permeability | <1,6E-12 | <1,5E-12 | <1,3E-12 | <1,0E-12 | <1,0E-12 | |

| Capillarity | 0 | 0 | 0 | 0 | 0 |

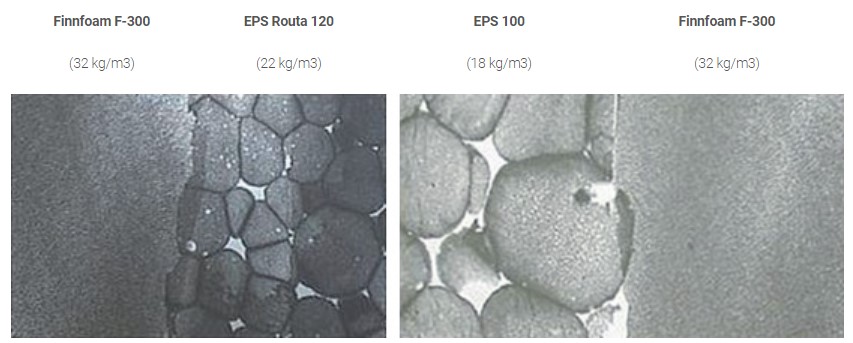

FINNFOAM’s cell structure is completely consistent and closed throughout the entire panel. The panel is covered by an impermeable skin that repels water. Year-long immersion tests have found that water is only able to reach the cells on the sawed surfaces of a panel (cell size 0.05–0.1 mm). Even after one year, the amount of moisture absorbed had not increased from the situation after two days.

Due to the closed and consistent cell structure, FINNFOAM also functions as a vapor barrier. The insulation panels do not allow capillary movement of water, and it is not necessary to protect them separately against moisture or freezing at the construction site or during transportation. However, for end use, the panels should be protected from direct UV radiation.

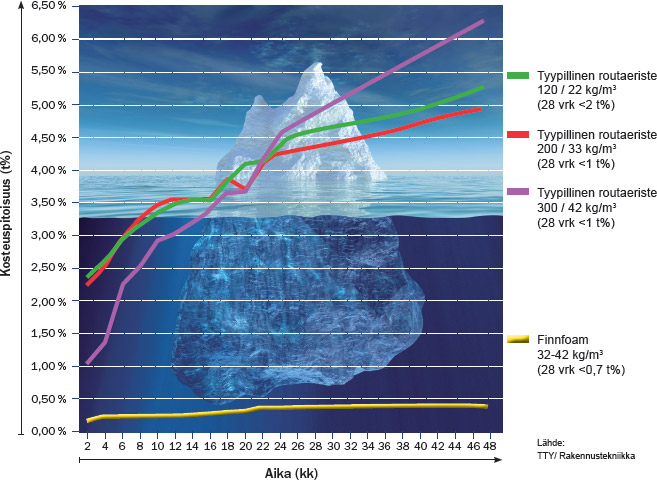

The absorptivity of water in the core is the same as that of pure polystyrene’s, i.e., only 0.1% of volume. This has been verified with long-term immersion freezing tests. The test provides the best representation of the actual conditions in which frost protection is used. The long-term immersion test (size of test sample 200 x 200 x thickness) performed at TTY, in which the sample was also frozen occasionally (freezing at 2 month intervals), reveals actual differences in the waterproofing of frost insulation products. In terms of the freezing cycles, the test in question was significantly less demanding than testing conducted in accordance with the EN standard, but it was longer in duration. FINNFOAM ensures reliable frost insulation!

LONG-TERM IMMERSION AND FREEZING TEST 48 MONTHS

VTT FROST PROTECTION TESTING, WHERE THE FROST INSULATION IS EXPOSED TO RAINWATER AND SUBJECTED TO LOAD