FF-EPS X 60S

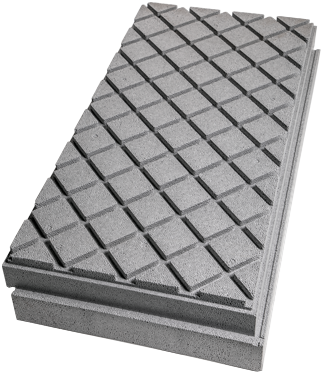

The FF-EPS M panels have a diamond-shaped grid on one side. The grooves are intended to function as a network of ventilation channels in flat roofs, for example, or to allow for better adhesion for concrete when cast directly on the panel. The material used for gray FF-EPS contains graphite, and its declared thermal conductivity (λD) is 0.031 W/mK, which is significantly higher than that of the traditional white EPS. FF-EPS X 60S is well-suited for use as thermal insulation in walls and roofs. The panels feature a tongue and groove edge on all sides and are available with a thickness of 320 mm. Other thicknesses can also be manufactured on order. The locking tongue and groove ensures that a single layer of panels will provide insulation without thermal bridging. The size of the panels is 600 x 1 200 mm, which allows for much easier handling and installation. The short-term compressive strength of FF-EPS X 60S panels is 60S. Due to the fire retardant used in the FF-EPS X 60S products, their fire class is E.

Material: Expanded polystyrene

Color: Graphite gray

FF-EPS X 60S

- Dimensions

- Technical details

| Value | Unit | According to EN 13163 | Standard | |

|---|---|---|---|---|

| Length | 1200 | mm | ||

| Width | 600 | mm | ||

| Thickness | 320 | mm |

| Value | Unit | According to EN 13163 | Standard | |

|---|---|---|---|---|

| Thermal conductivity | EN 13163 | |||

| λ Declared | 0,031 | W/(m K) | EN 12667, EN 12939 | |

| Thermal resistance, Rᴅ | 10,3 | m²K/W | EN 12667, EN 12939 | |

| Compressive strength, short-term 45 days, ≥ 30mm | 60 | kPa | CS (10/Y)60 | EN 826 |

| Bending strength | 100 | kPa | BS100 | EN 12089 |

| Tensile strength perpendicular to surfaces | 130 | kPa | TR130 | EN 1607 |

| Shearing strength | 50 | kPa | SS50 | EN 12090 |

| Design stability | 1 | DS (70,90)1 | EN 1604 | |

| Water vapor permeability | 0,015 - 0,030 | mg/(Pa·h·m) | EN 12086 | |

| Fire class | E | EN 13501-1 | ||

| Service temperature when subject to load | -150... + 75 | C° | ||

| Indoor air emission class | M1 |