USING FF- EPS INSULATION AS THERMAL INSULATION FOR ROOFS

Designed for insulating ceilings and roofs, FF-EPS is highly cost-effective and safe in terms of moisture performance, with a declared thermal conductivity of 0.031 W/mK. FF-EPS insulation products are suitable for new construction, low-energy, passive, and zero-energy construction, as well as for renovation and supplementary thermal insulation of older buildings.

FF-EPS insulation products are excellently suited for use with different frame materials in roofs. The frame could consist of wood, steel, concrete, or lightweight concrete (Siporex). Structures that are thermally insulated with FF-EPS always require a separate air or vapor barrier layer, as the product does not have a high enough water vapor resistance to function as vapor barrier on its own. A vapor barrier can be constructed using FF-PIR thermal insulation products or traditional membrane-type solutions. The locking tongue and groove edge profile of the FF-EPS panels provides an easy way to ensure that the thermal insulation is continuous and leak-proof. It is not necessary to apply PU foam to tongue and groove joints, but any lead-throughs, for example, should still be sealed with an elastic PU foam sealant. FF-PIR polyurethane insulation is also commonly used for low pitch roofs.

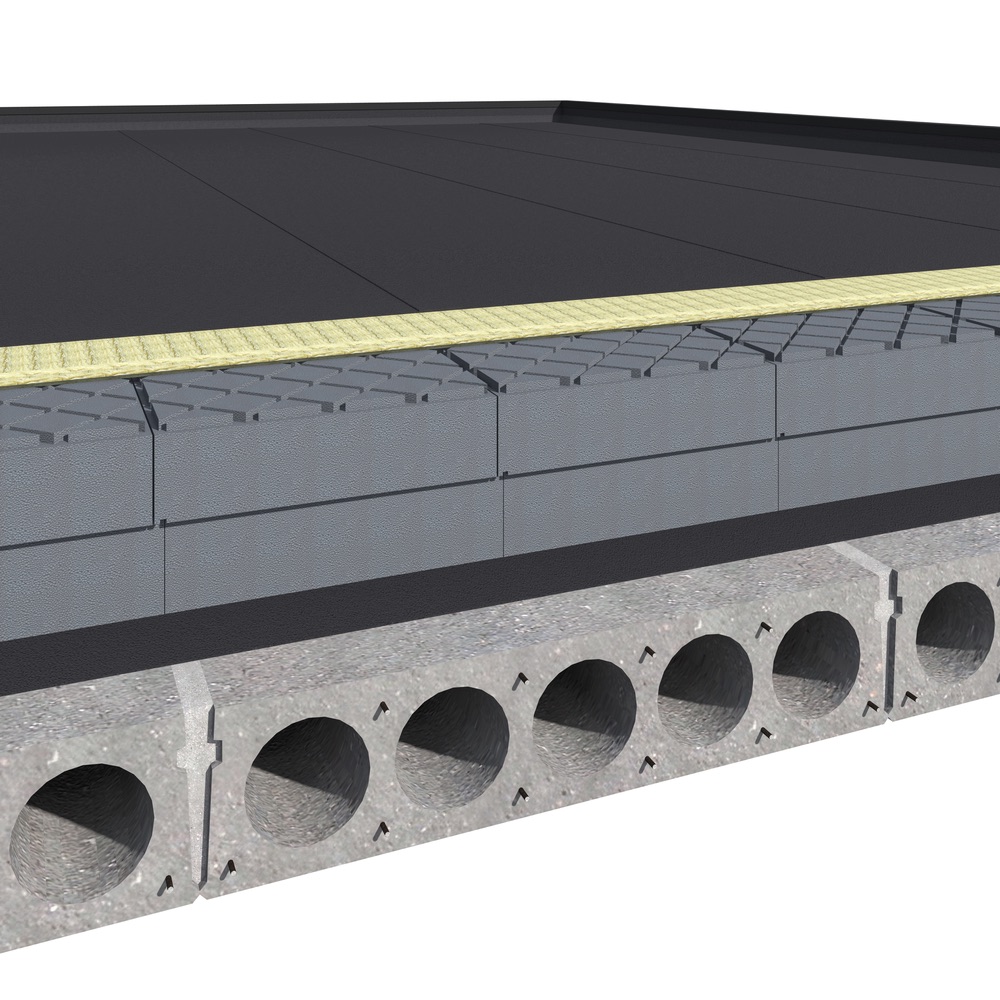

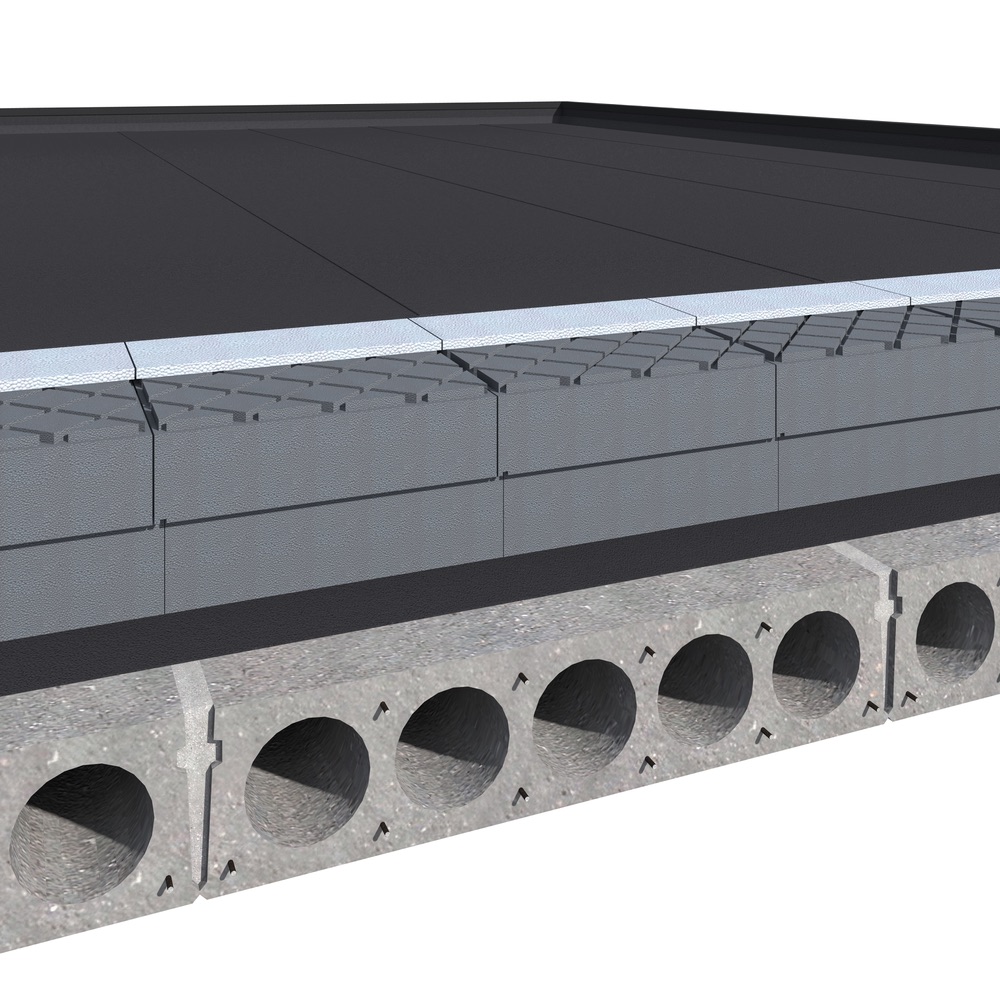

THE BEARING ROOF STRUCTURE DETERMINES THE INSULATION SOLUTION

FF-EPS insulation products are compatible with all commonly used roof framework materials. FF-EPS is a highly cost-effective thermal insulation material for flat and sloped roofs. For example, a U value of 0.09, which is the current requirement for roofs, can be achieved with a structure consisting of a hollow-core slab, vapor barrier, FF-EPS X 60S/320 mm, a 20-mm bearing layer of wool, and roofing. This construction ensures that the overall thickness of the structure remains at a reasonable level and eliminates the tracking risk on the roof even around access points. Today, a significant number of technical equipment is placed on roofs, which requires moving about on the roof, and thus the thermal insulation materials used on flat or low pitch roofs must be able to withstand this stress without tracking. The sturdy thermal insulation products manufactured by Finnfoam Oy (FINNFOAM, FF-EPS, FF-PIR) eliminate the tracking risk.

NEW FF-EPS 60S SILENT

The FF-EPS 60S SILENT panels are coated on one side with a 15–20 mm thick special layer that offers excellent sound-proofing and fire resistance and is suitable for use as a base for cladding. FF-EPS 60S SILENT panels have a deep 10 mm grid pattern below the coating, which is intended to function as a network of ventilation channels on low pitch roofs. FF-EPS 60S SILENT reduces the cubic volume of material lifted on to the roof and allows for faster installation. The required U value of 0.09 can be achieved with a single 320-mm thick panel, which allows for faster roof construction.

PRODUCT VIDEO:

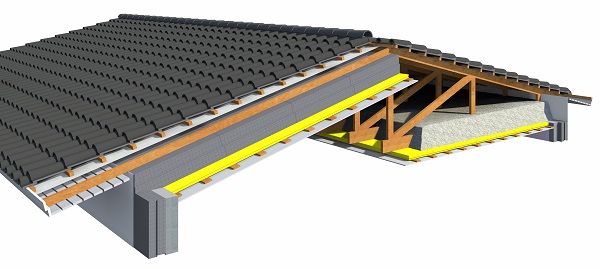

SLOPING TIMBER STRUCTURES

For sloping timber structures, the most effective roof solution with minimal thermal bridging can be achieved if the FF-EPS insulation is installed as a continuous layer on top of the load-bearing structure. With glued laminated beams, it is also possible to utilize a structure where FINNFOAM or FF-PIR panels are installed on the bottom surface of the joists as a vapor barrier, and FF-EPS panels with the thickness required to reach the desired U value are foam sealed in between the joists.

The thickness of insulation is determined based on the desired U value. The below chart presents some example structures.

| Framework | Insulation/framework | FF-PIR | U value W/m2K |

| Hollow-core slab | Insulation on top of hollow-core slab | FF-EPS X 60S/200 mm + 20–30-mm bearing layer of wool | 0,14 |

| Hollow-core slab | Insulation on top of hollow-core slab | FF-EPS X 60S/320 mm + 20–30-mm bearing layer of wool | 0,09 |

| Hollow-core slab | Insulation on top of hollow-core slab | FF-EPS X 60S/400 mm + 30-mm bearing layer of wool | 0,07 |

| Hollow-core slab | Insulation on top of hollow-core slab | FF-EPS 60S X SILENT 320mm | 0,09 |

| Double T-slab | Insulation on top of slab | FF-EPS 60S/320 mm + 20–30-mm bearing layer of wool | 0,09 |

| Glued laminated beam height > 400 mm | FF-PIR 50 mm or Finnfoam 70 mm on the inside | FF-EPS 60S/200 + 200 mm in between | 0,07 |