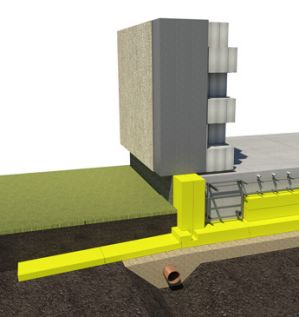

Edge-Reinforced Slabs

IN 2016, FINNFOAM INTRODUCED A NEW FOUNDATION SOLUTION FOR EDGE-REINFORCED SLABS

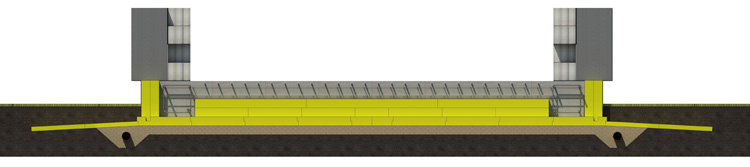

The solution is based on sturdy FINNFOAM thermal insulation panels that are cut into a custom shape to create a casting mold that is not dismantled after casting. An edge-reinforced slab, which is thermally insulated throughout, provides the best possible foundation solution for passive and zero-energy houses, because it completely eliminates thermal bridging from the foundation. The low water vapor permeability of FINNFOAM prevents transfer of moisture from the ground to the slab. Due to the high compressive strength of FINNFOAM, the thermal insulation will also not be affected by compression-related issues.

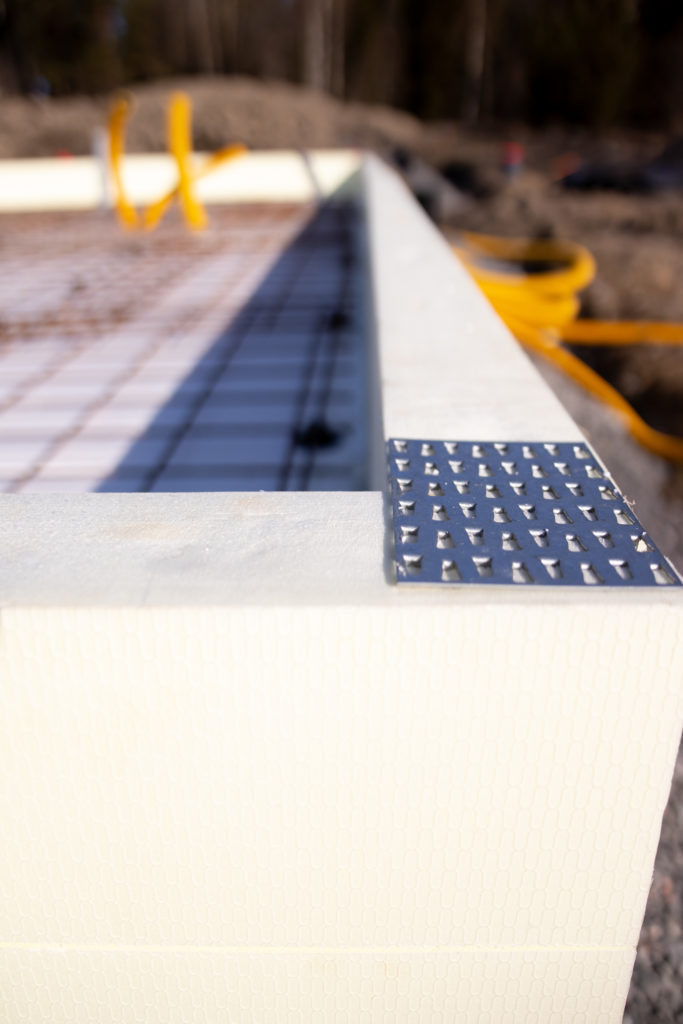

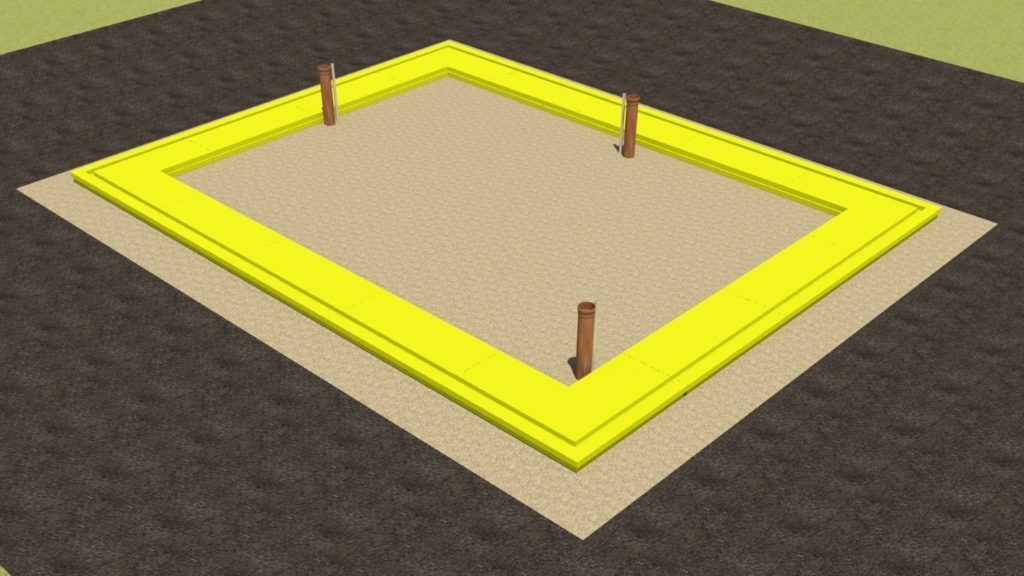

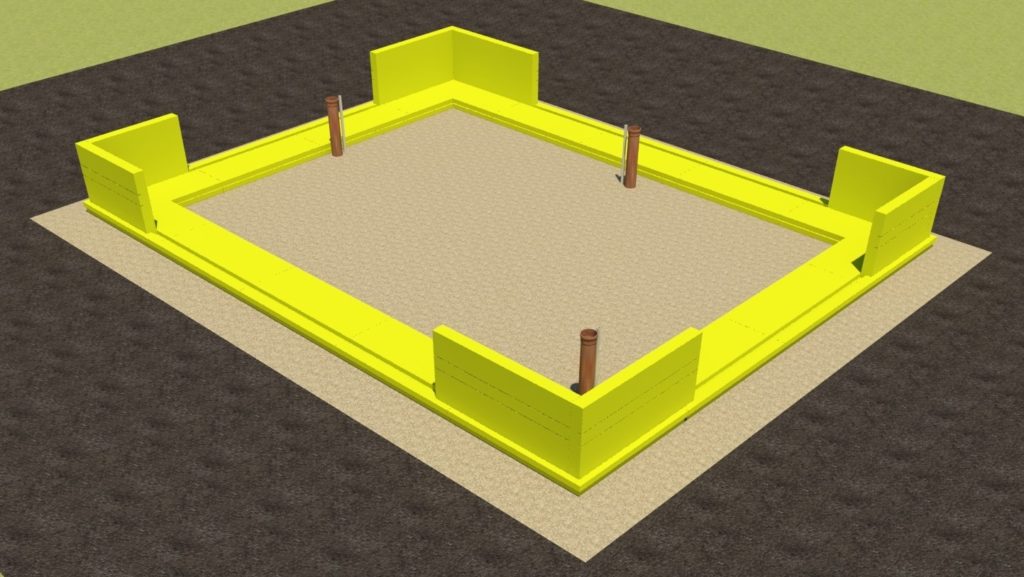

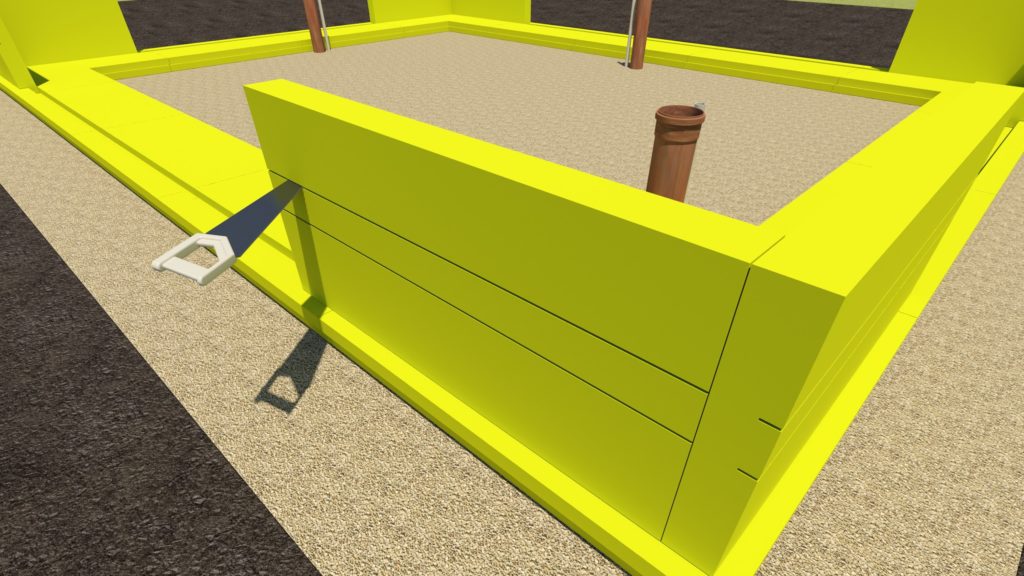

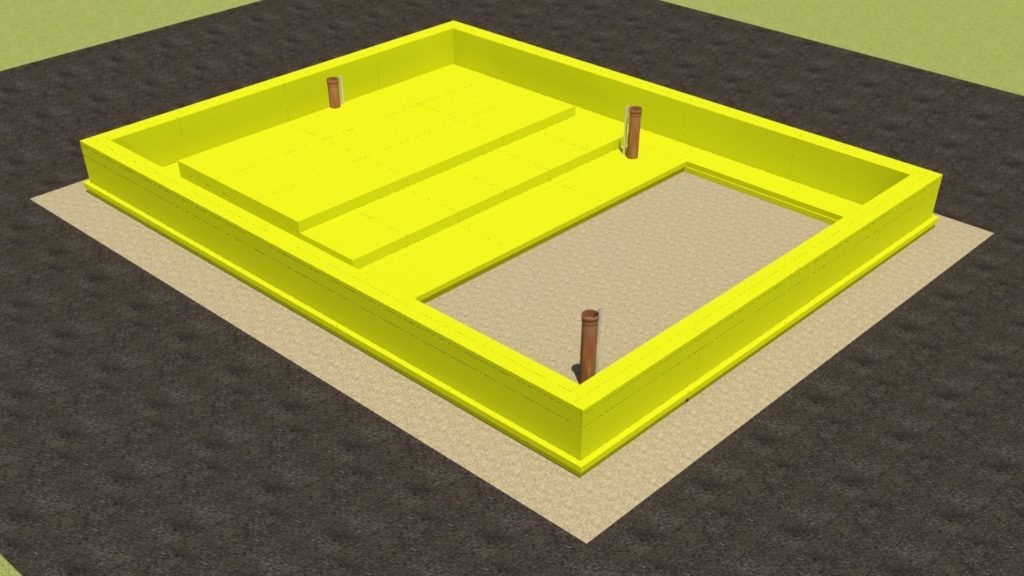

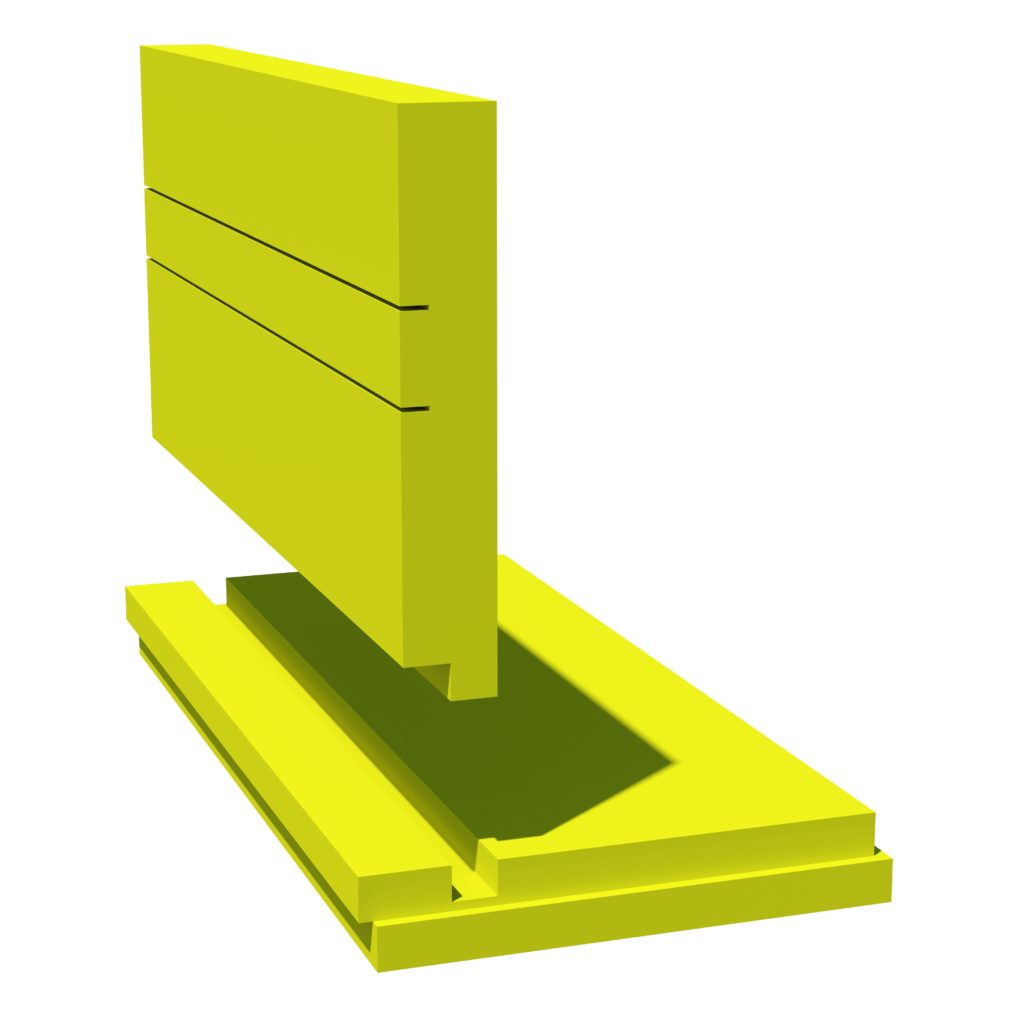

The panels are laid on a smooth, sealed base. The mold construction begins by placing down the FINNFOAM LB300 bottom pieces for the edge molds, after which the upright FINNFOAM LS300 walls are attached. The upright FINNFOAM LS300 walls are 100 mm thick, and a second 100-mm panel of regular FINNFOAM is usually placed on the exterior side and secured with insulation anchors to ensure sufficient thermal insulation of the structure, and to provide support for the walls during casting. In addition, the wall are further secured using 5 mm stainless steel supports, which are placed at approximately 1 meter intervals and attached to the slab’s reinforcement.

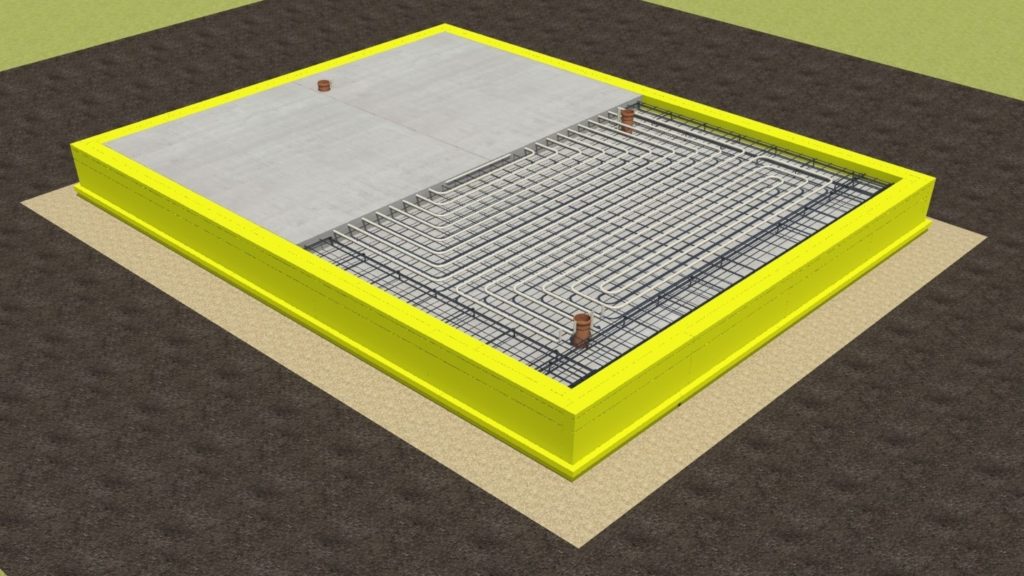

A 200–300 mm thick layer of FINNFOAM thermal insulation is placed as thermal insulation on the interior side of the edge-reinforcement in accordance with the desired U value. Next, the slab is reinforced according to the plans, the necessary pipelines are laid, and the edge-reinforced slab is cast. This solution significantly facilitates and speeds up the creation of an edge-reinforced slab and completely eliminates thermal bridging from the slab.

Further information on the products designed for this solution (LS300 and LB300) can be found here.